Project Report On Replacement Of Crush Sand To

project report on sand replacement by stone crush dust in concrete replacement of sand with quarry dust model project report for m sand unit replacement sand Read more project report on replacement of sand bu crushed rock finesProject Report On Replacement Of Crush Sand To Riversand India Stone Dust in Concrete: Effect on Compressive Strength abruptly with increase in replacement level of river sand By replacing natural river sand with stone dust (10% 100%) in creased compressive strength (8% 27%) can be Project Report On Replacement Of Crush Sand To Project Report On Sand Replacement By Stone Crush Dust In Application; CONTACT US; The project was undertaken with following objectives EXPERIMENTAL INVESTIGATIONS ON REPLACEMENT OF SAND BY QUARRY DUST IN CONCRETE Read moreApplication Use And Objectives Of Quarry Dust Used An investigation on effect of quarry dust as sand replacement on A study on the effect of quarry dust as sand replacement concrete by using quarry as partial sand sand replacement material This report a report on partial replacement of sand by using robo This project describes the feasibility of using the marble sludge dust in concrete production as partial replacement of cement In INDIA, the marble and granite stone processing is one of the most thriving industry the effects if varying marble dust contents on the physical and mechanical properties of fresh and hardened concrete have been investigatedProject on Partial Replacement of Cement with Marble

Use of Recycled Aggregates in Construction

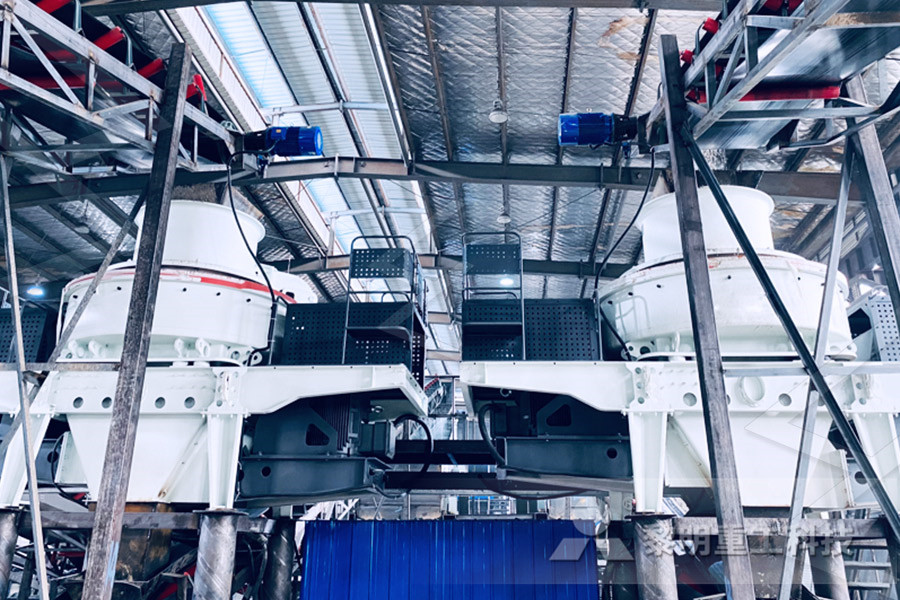

Partial replacement of fine aggregate in concrete and asphaltic concrete Available in NSW Reused Byproduct Aggregates Aircooled BF Slag Slowly aircooled crystalline iron slag – crushed and screened Also available as uncrushed slag All structural grade concrete Commercially available from Port Kembla and Whyalla Granulated BF Slag Sandlike rapidly quenched iron slag with high volume Screening is done to eliminate dust particles and Washing of sand eliminates very fine particles present within The end product will satisfy all the requirements of IS:383 and can be used in Concrete construction The VSI Plants are available capacity upto 400Ton Per Hour(TPH) Manufactured Sand (M Sand)Use of Manufactured Sand in Concrete and Conventional concrete prepared with Msand shows superior rebar bond strength and slip resistance when compared to that with natural sand [15]Presence of less than 13% stone dust (Fines) shows positive correlation with the longterm compressive strength gain in Msand concrete [16]Characteristics of Cement Mortar with Msand as Concrete Mix Design Report The basic formula is simple, sand, crush rock aggregate, water and cement Concrete can take nearly any shape that’s why it is being used in mega dam structures, sky scrapers or bridges or any structure on earth The entire stone dust Concrete Mix Design Report SlideShareDhanaraj Mohan Patil and Dr Keshav K Sangle carried out research work in “Experimental Investigation of Waste Glass Powder as Partial Replacement of Cement in Concrete”, their conclusion is that at the level of 20% replacement of cement by glass powder meets maximum strength as compare to that of normal concrete and other percentage of replacement of cementEffect Of Glass Powder On Compressive Strength Of

a report on partial replacement of sand by using robo

a report on partial replacement of sand by using robo sand in high performance concrete with ggbs and robo sand high performance concrete with ggbs and robo sand venu malagavelli department of civil engineering, »More detailedQuality of sand is as much of importance as other materials for concrete Aggregate most of which pass through 475 mm IS sieve is known as fine aggregate Fine aggregate shall consists of natural sand, crushed stone sand, crushed gravel sand stone dust or arable dust, fly ash and broken brick (burnt clay)Testing of Sand Quality at Construction Site for Concrete Screening is done to eliminate dust particles and Washing of sand eliminates very fine particles present within The end product will satisfy all the requirements of IS:383 and can be used in Concrete construction The VSI Plants are available capacity upto 400Ton Per Hour(TPH) Manufactured Sand (M Sand)Use of Manufactured Sand in Concrete and Focusing on the above problems, granite dust was used as partial fly ash replacement in granite manufactured sand concrete to achieve the comprehensive application of granite dust and manufactured sand The concrete slump was designed as 180 ± 10 mm, meeting the pumping requirements The effects of the workability, mechanical property Effect of granite dust on mechanical and some potential use in concrete and/or road construction materials 12 Classification of Aggregates For the purpose of this report, the following classifications are adopted Natural aggregate Construction aggregates produced from natural sources such as gravel and sand, and extractive products such as crushed rock Manufactured aggregateUse of Recycled Aggregates in Construction

Concrete Production an overview ScienceDirect

Concrete production is a highly intensive energyconsuming process and presently facing a number of challenges in reducing the carbon footprint and making it more economic Sustainable technologies in maintaining concrete structures are proving to be a great challenge Microbially induced carbonate precipitation (MICP) has developed as a novel and sustainable technique in improving the The Effect of Aggregate Properties on Concrete Concrete is a mixture of cementious material, aggregate, and water Aggregate is commonly considered inert filler, which accounts for 60 to 80 percent of the volume and 70 to 85 percent of the weight of concreteThe Effect of Aggregate Properties on Concrete Higher concrete strength compared to river sand used for concreting Lesser concrete compared to M Sand Silt Content Zero silt Minimum permissible silt content is 3% Anything more than 3% is harmful to the concrete durability We can expect 5 20% slit content in medium quality river sand Over Sized Materials 0% Since it is artificially M Sand Vs River Sand (Natural Sand) materialtree Natural soil, flyash, sand, stone dust, river bed materials, reclaimed asphalt pavement, low quality aggregates etc are considered as ingredients of pavements with cemented base/subbaseCEMENT STABILIZATION ON ROAD BASES Sand and gravel obtain maximum density in either a fully dry or saturated state Testing curves are relatively flat so density can be obtained regardless of water content The tables on the following pages give a basic indication of soils used in particular construction applications [See Figures 5, Soil Compaction Handbook Multiquip

Use of Recycled Aggregates in Construction

potential use in concrete and/or road construction materials 12 Classification of Aggregates For the purpose of this report, the following classifications are adopted Natural aggregate Construction aggregates produced from natural sources such as gravel and sand, and extractive products such as crushed rock Manufactured aggregate Describing his project, Henry Louis Miller states: “Recycling plastics is a difficult, energy intensive process, and yields a product that is inferior to the virgin material the concrete Plastic Concrete: Building Bricks Made From Landfill Respirable crystalline silica – very small particles at least 100 times smaller than ordinary sand you might find on beaches and playgrounds – is created when cutting, sawing, grinding, drilling, and crushing stone, rock, concrete, brick, block, and mortar Activities such as abrasive blasting with sand; sawing brick or concrete; sanding or Silica, Crystalline Overview Occupational Safety and Properties of Hardened Concrete 1 Strength: Concrete is strong in compression but relatively weak in tension and bending It takes a great deal of force to Reinforcing Civil EngineersJust covering the pipe on top with sand would be a poor practice What is the Proper Material for Bedding Buried Sewer or Water Pipes? Sewer lines in sand, possibly in pea gravel: Our contractor for the sewer line replacement project documented in this article used clean sand for bedding the new sewer piping Sand was specified by our local Sewer line replacement guide the need for sand

Clay Brick an overview ScienceDirect Topics

Concrete blocks, stone and mortar expand or contract with changes in moisture content but, unlike clay bricks, they undergo longterm drying shrinkage Moisture movement of brick, block or stone masonry is therefore the composite effect of shortterm changes in moisture content and irreversible expansion/drying shrinkage of the masonry units Fill a space with concrete (150 lb/ft³) Let’s say we need to fill in an area of space measuring 5 feet long, 3 feet wide and 2 inches deep with concrete which costs $50 per US short ton I want to work out an estimate for the volume of concrete required, how much it will weigh and the total expected cost of the projectAGGREGATE CALCULATOR [How Much Aggregate Do At one time it was thought that a prime coat was an essential element of good pavement construction However, in recent years some engineers have eliminated the use of a prime, especially when asphalt layer(s) (surface and/or base) is 4 inches or more in thicknessAsphalt Pavement Construction Asphalt InstituteCrushed Granite Cost Installing crushed or decomposed granite on a 400square foot area costs from $125 to $300, or between $030 and $070 per square footThe cost of the materials alone is between $35 and $60 per inch of coverage, assuming you use basic crushed granite The most important cost variables are the quality of the granite and depth of coverage2021 Cost of Decomposed Granite Crushed Granite Sieves should also be cleaned before use The actual sieving operation can be done by hand or as in modern laboratories by a sieve shaker Grading curves with the ordinates representing cumulative percentage passing and the abscissa the sieve opening to logarithmic scale can be drawn to study the results of sieve analysis of soilSieve Analysis of Soil; Its Determination, Theory